Types of Plastic Conduits and Their Applications

Types of Plastic Conduits and Their Applications

Plastic conduits play a crucial role in protecting electrical wiring in various environments. The most common types of plastic conduits include Rigid PVC Conduit, Electrical Non-Metallic Tubing (ENT), Liquid-Tight Flexible Non-Metallic Conduit, and High-Density Polyethylene (HDPE) Conduit. Each of these conduits has unique features that make them ideal for specific applications.

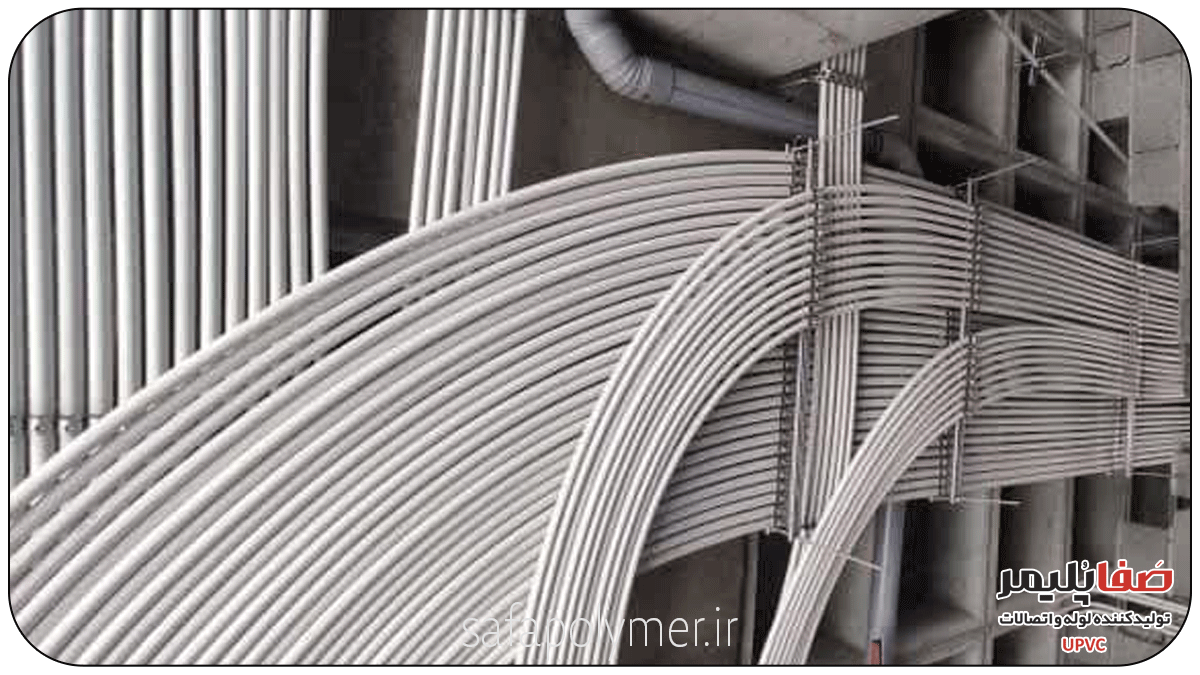

1. Rigid PVC Conduit

Rigid PVC conduits are one of the most widely used plastic conduits due to their strength, corrosion resistance, and long lifespan. They are commonly used in residential, commercial, and industrial settings.

- High resistance to chemicals and harsh conditions

- Suitable for indoor and outdoor installations

- Secure connection with solvent cement

- Smooth interior for easy wire pulling

- Flame-resistant, enhancing fire safety

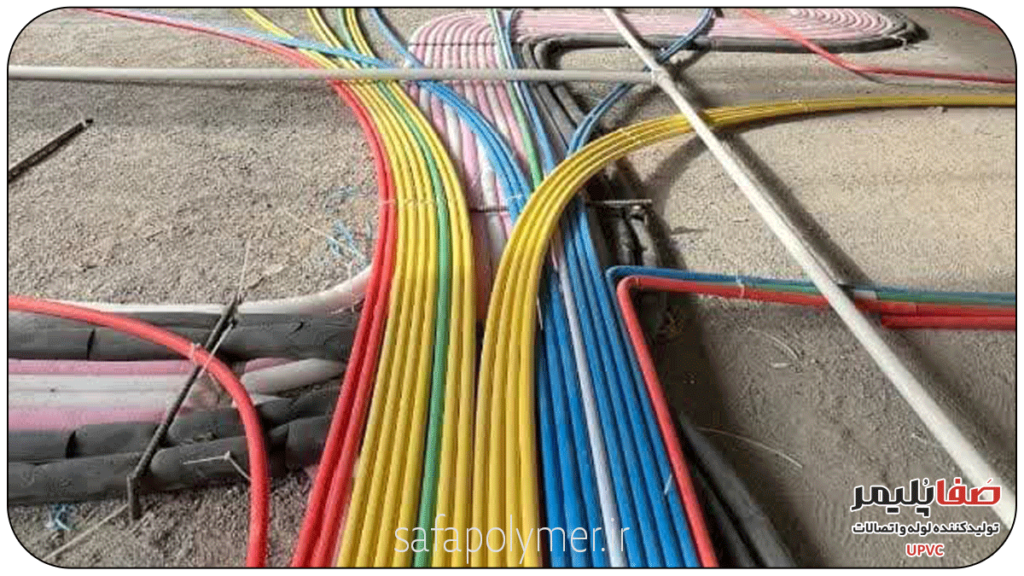

2. Electrical Non-Metallic Tubing (ENT)

ENT is a lightweight and flexible plastic conduit widely used in residential and commercial projects due to its ease of installation. Its flexibility allows it to pass easily through walls, ceilings, and floors, making it ideal for renovations and retrofit projects.

- Suitable for low-voltage wiring

- Reduces installation costs due to its lightweight and ease of handling

- Color-coded for easy identification of different wiring systems (power, telecommunications, fire alarm, etc.)

- Compatible with various fittings and connectors

3. Liquid-Tight Flexible Non-Metallic Conduit

This type of flexible and waterproof conduit is designed for environments where moisture, liquids, and water exposure are significant concerns. It is highly useful in outdoor applications, industrial settings, and humid areas.

- Combines flexibility with strong water resistance

- PVC coating for moisture and corrosion protection

- Suitable for HVAC systems, outdoor lighting, marine, and industrial environments

- Can be used with liquid-tight fittings for a fully sealed system

4. High-Density Polyethylene (HDPE) Conduit

HDPE conduit is an excellent choice for underground and outdoor installations due to its high density and durability. Its exceptional resistance to impact, chemicals, and UV radiation makes it widely used in telecommunications and fiber optic cable protection.

- Resistant to corrosion, impact, and harsh weather conditions

- Ideal for trenchless installations and horizontal directional drilling

- Reduced internal friction for easy cable pulling

- Available in various sizes and supplied in long coils to minimize joint connections

Conclusion

The choice of the right plastic conduit depends on environmental conditions, application type, and project requirements. Rigid PVC conduits are ideal for general applications, ENT conduits for lightweight and renovation projects, liquid-tight flexible conduits for moisture-prone environments, and HDPE conduits for underground infrastructure. Each of these conduits plays a vital role in protecting electrical wiring and enhancing system safety.