Discover the Applications of Plastic Pipes

Discover the Applications of Plastic Pipes

- Residential Applications

Plastic pipes are widely used in residential environments due to their safety, efficiency, and ease of installation. In homes, they are used for both indoor and outdoor wiring, providing a strong conduit that protects electrical cables from physical damage, moisture, and exposure to various elements. Indoors, plastic pipes typically run through walls, ceilings, and floors to ensure electrical wiring remains secure and insulated. They are especially useful in new constructions and renovations where conduits can be easily integrated into the building framework.

For outdoor applications, such as garden lighting, outdoor power outlets, and pool wiring, plastic pipes offer excellent resistance to weather conditions, preventing degradation from UV radiation, rain, and temperature fluctuations. Additionally, their non-conductive nature adds an extra layer of safety by reducing the risk of electrical shock.

- Commercial Applications

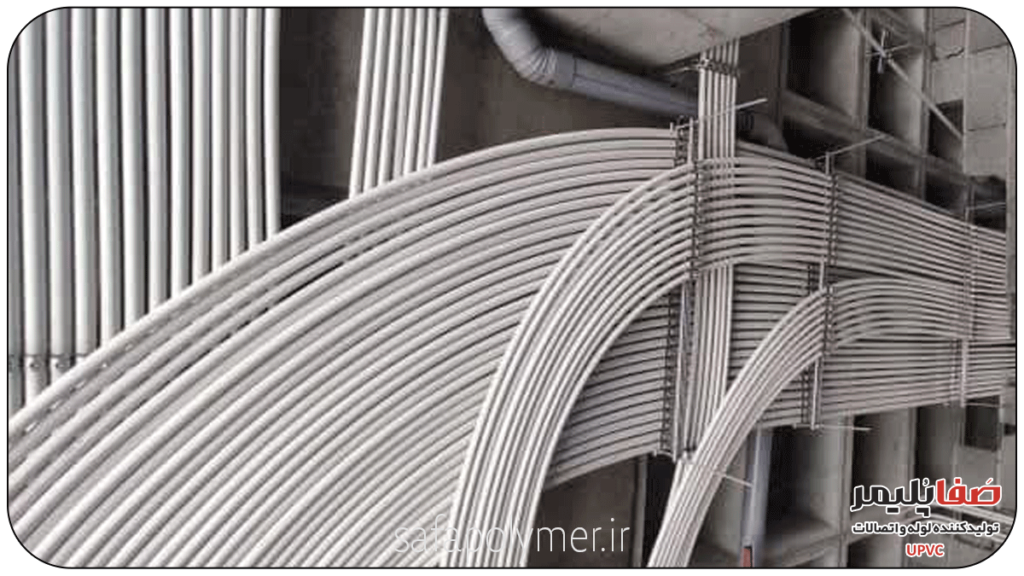

In commercial environments, plastic pipes play a crucial role in managing the complex wiring systems required in office buildings, shopping centers, hospitals, and educational institutions. These environments often involve extensive and intricate electrical networks that require reliable protection and organization.

Plastic pipes provide the flexibility and durability needed to meet these demands, allowing for the efficient routing of electrical cables through walls, ceilings, and under floors. They help maintain a neat and organized installation, which is essential for safety and maintenance purposes.

For example, in office buildings, plastic pipes are used to manage extensive cabling for computer networks, lighting, and HVAC systems. Their ease of installation and adaptability to tight spaces make them an ideal option for retrofitting older buildings where space constraints can pose significant challenges. Additionally, plastic pipes offer resistance to fire and exposure to chemicals, adding an extra layer of protection in environments such as hospitals and laboratories where strict safety standards are required.

- Industrial Applications

Industrial environments present unique challenges due to the harsh conditions often present, such as exposure to chemicals, extreme temperatures, and mechanical wear. Plastic pipes are well-suited for these demanding settings, protecting electrical wiring in factories, warehouses, and manufacturing plants. Their resistance to chemicals and moisture ensures that wiring remains safe from corrosive substances commonly found in industrial processes.

Furthermore, plastic pipes can withstand significant physical impacts, protecting cables from accidental damage caused by machinery or heavy equipment. They are used in factories to guide power and control cables to various machines and production lines, ensuring a reliable and uninterrupted power supply.

The flexibility of plastic pipes also allows for easy modification and expansion of the electrical system as industrial setups evolve. In warehouses, plastic pipes help organize and protect the extensive wiring required for lighting, security systems, and automated inventory systems.

- Specialized Applications

Plastic pipes are also used in specialized applications where their unique properties provide significant advantages. For example, in solar panel installations, plastic pipes offer a durable and weather-resistant conduit for electrical cables connecting the panels to the inverter and power grid. Their resistance to UV radiation and harsh weather conditions ensures long-term reliability and safety.

Additionally, plastic pipes are commonly used in underground wiring applications, such as the installation of buried power cables for street lighting, telecommunications, and power distribution networks. Their resistance to moisture and corrosion makes them ideal for these applications, ensuring that the electrical system remains protected even in challenging underground environments.

Another specialized application includes the use of plastic conduits in marine and coastal installations, where exposure to saltwater and high humidity can rapidly degrade other materials. The non-corrosive nature of plastic pipes makes them an excellent choice for these environments, protecting electrical wiring in boats, docks, and coastal facilities.