Applications and Advantages of Flame-Resistant Cold-Bending UPVC Electrical Conduits

Applications and Advantages of Flame-Resistant Cold-Bending UPVC Electrical Conduits in Electrical Wiring Industry

Flame-resistant cold-bending UPVC electrical conduits are among the most advanced and efficient options for protecting electrical wiring in residential, commercial, and industrial projects. These conduits are widely used in electrical installations due to their excellent mechanical properties, high resistance to heat and chemicals, flexibility, and enhanced safety.

Advantages of Using Flame-Resistant Cold-Bending UPVC Electrical Conduits

- Heat and Fire Resistance

UPVC electrical conduits are made from flame-retardant polymeric materials that withstand high temperatures and prevent fire from spreading. This makes them a safe option for residential, office, and industrial buildings where fire safety is a priority. - Flexibility and Easy Installation

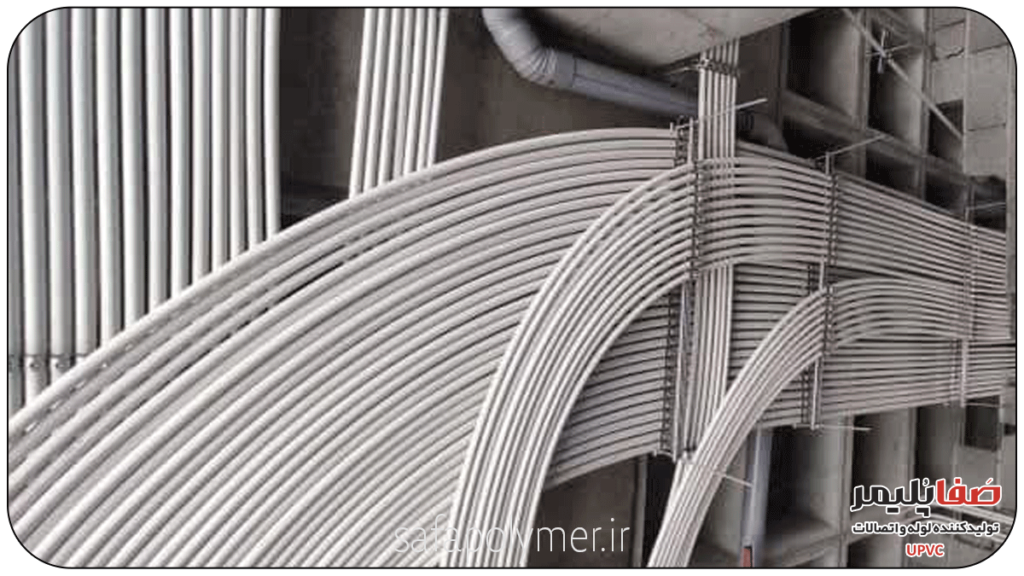

One of the major advantages of these conduits is their ability to be bent cold without requiring heat or specialized tools. This feature reduces installation time and costs, making electrical projects more efficient. Additionally, it allows for cable routing in complex pathways. - Corrosion and Moisture Resistance

Unlike metal conduits that rust and corrode in humid environments, UPVC conduits are entirely resistant to water and moisture. This makes them ideal for underground installations, industrial projects, and high-humidity environments such as boiler rooms and marine facilities. - High Electrical Insulation and Enhanced Safety

Due to their excellent dielectric properties, UPVC conduits do not conduct electricity, reducing the risk of electric shocks and improving the safety of electrical networks. This is especially beneficial in residential and commercial buildings where occupant safety is crucial. - Lightweight and Durable

Despite their high strength, these conduits are much lighter than metal alternatives, making transportation and installation faster and easier. Their durability reduces maintenance needs over time. - Chemical and Environmental Resistance

UPVC is resistant to many corrosive chemicals, acids, and solvents, making it a suitable choice for industrial environments. Additionally, these conduits are UV-resistant, preventing discoloration and brittleness from direct sunlight exposure. - Reduced Installation and Maintenance Costs

Due to their ease of installation, lightweight design, and high durability, UPVC electrical conduits help reduce labor and equipment costs. Their long lifespan and minimal maintenance requirements further lower long-term expenses.

Applications of Flame-Resistant Cold-Bending UPVC Electrical Conduits

Due to their numerous advantages, these conduits are widely used in various electrical wiring projects, including:

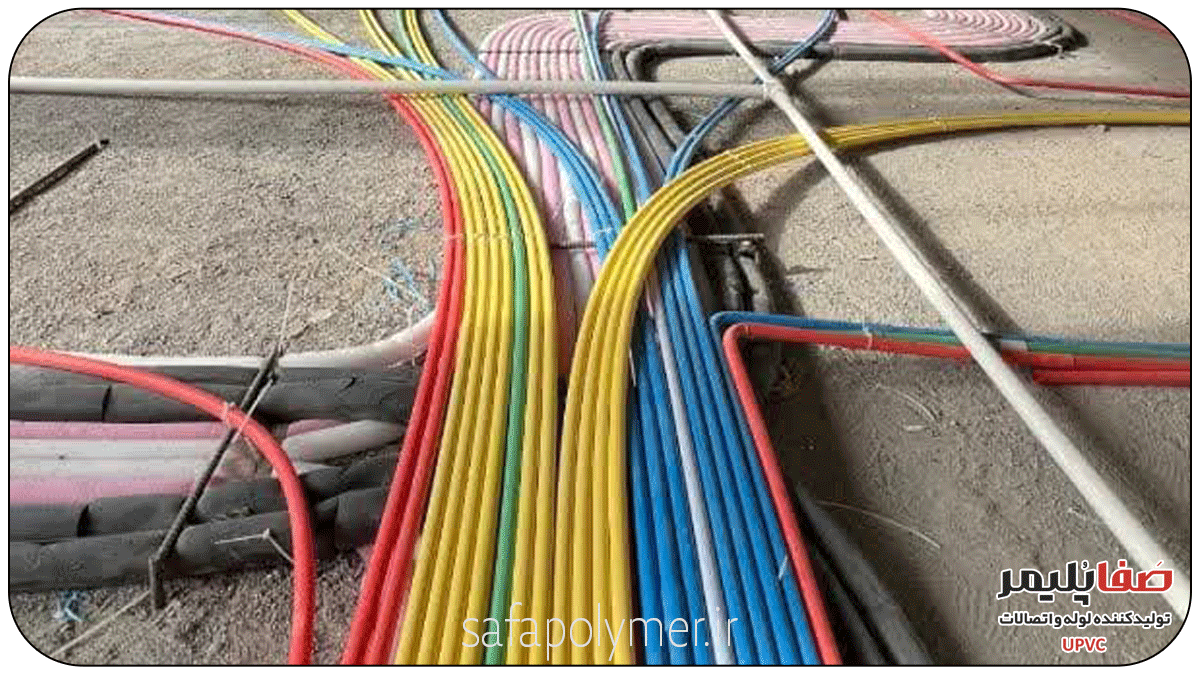

- Residential and Commercial Buildings

These conduits are used in residential towers, commercial complexes, and office buildings due to their high safety, easy installation, and long lifespan. - Industrial Facilities and Factories

In industrial environments requiring special protection for electrical wiring against heat, chemicals, and moisture, UPVC conduits are the best option. - Underground Wiring and Urban Cabling Projects

Due to their high resistance to corrosion and environmental factors, these conduits are used for underground cabling and power transmission in cities, subways, and tunnels. - Outdoor Lighting Systems

These conduits are used for power cable routing in parks, streets, and urban lighting projects due to their resistance to weather changes and sunlight exposure. - Power Plants and Electrical Substations

In power generation and distribution infrastructures, these conduits protect electrical cables from physical and environmental damage.

Conclusion

Flame-resistant cold-bending UPVC electrical conduits are an ideal choice for electrical wiring projects due to their heat and fire resistance, high flexibility, corrosion and chemical resistance, lightweight structure, and cost efficiency. Their use not only enhances the safety and durability of electrical installations but also significantly reduces installation and maintenance costs