Advantages of Using Plastic Pipes

Advantages of Using Plastic Pipes

1- Durability and Longevity

✅ Corrosion Resistance: One of the most significant advantages of plastic pipes is their high resistance to corrosion. Unlike metal pipes, they do not rust or corrode when exposed to moisture, chemicals, or harsh environmental conditions. This makes them an excellent choice for outdoor installations, underground applications, and environments with high humidity or exposure to chemicals, such as agricultural settings and chemical plants.

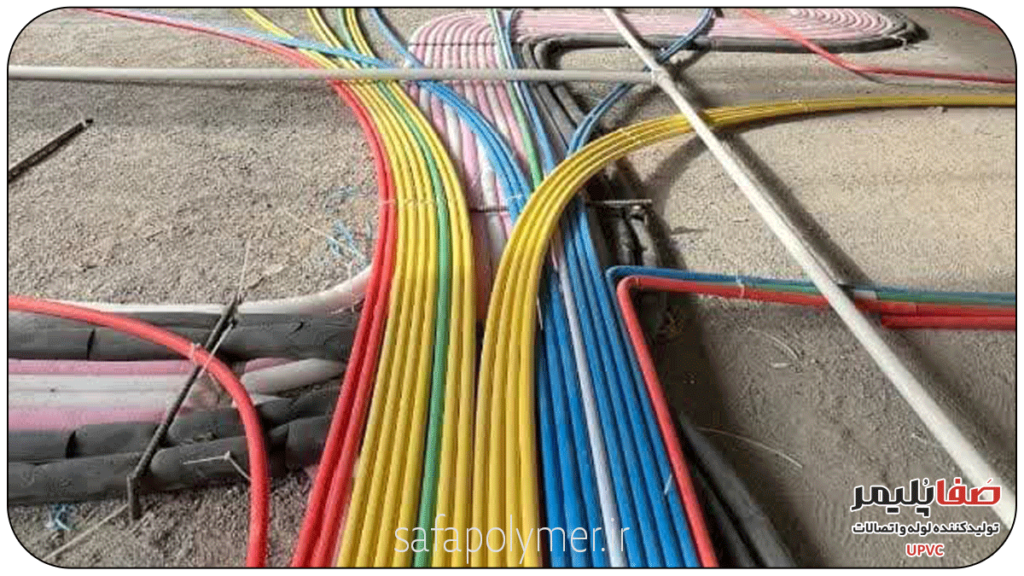

✅ Flexibility and Impact Resistance: Plastic pipes are inherently more flexible than metal pipes, allowing them to absorb shocks and resist cracking or breaking. This flexibility makes them particularly useful in applications where the conduit may be exposed to movement or vibrations, such as machinery or seismic zones. Additionally, their impact resistance ensures they maintain their structural integrity even under physical pressure.

2- Cost Considerations

💰 Lower Material Costs: The cost of raw materials and manufacturing processes for plastic pipes is generally lower than that of metal pipes. This makes them a more budget-friendly option for many projects, especially those with financial constraints.

💰 Reduced Installation Costs: Due to their lightweight nature, plastic pipes are easier to transport, handle, and install, significantly reducing labor costs. They do not require specialized tools for cutting or joining, simplifying the installation process and lowering overall expenses.

3- Ease of Installation

🛠️ Lightweight and Easy Handling: Plastic pipes are much lighter compared to metal pipes, making transportation and installation considerably easier. This ease of use is particularly beneficial for large-scale installations or in hard-to-reach areas.

🛠️ Simple Cutting and Joining: Plastic pipes can be easily cut using basic tools, and their connections typically involve solvent cement or simple connectors. This streamlined installation process saves time and reduces the need for specialized labor.

4- Environmental Impact

🌍 Non-Reactive and Recyclable: Many plastic pipes are made from recyclable materials and do not release harmful substances into the environment. Advances in plastic technology, such as LSZH (Low Smoke Zero Halogen) pipes, have made plastic pipes an environmentally friendly option, as they emit fewer toxic gases in the event of a fire.

🌍 Energy Efficiency in Manufacturing: The production of plastic pipes generally requires less energy compared to metal pipes, resulting in a lower carbon footprint. This makes plastic pipes a more sustainable choice in terms of energy consumption.

5- Specialized Applications

🏠 Residential and Commercial Applications: Plastic pipes are widely used in residential and commercial environments due to their affordability, ease of installation, and sufficient protection for general electrical wiring needs. They are ideal for running wiring through walls, ceilings, and floors in homes, offices, and retail spaces.

🏗️ Underground and Outdoor Installations: Their resistance to moisture and corrosion makes plastic pipes an excellent choice for underground and outdoor applications, such as running electrical wiring for outdoor lighting, garden features, and external buildings.

✨ Plastic pipes offer the perfect combination of durability, cost-effectiveness, ease of installation, and environmental sustainability, making them a reliable choice for a wide range of electrical and construction applications. 🚀